AccueilHome > Band dryers

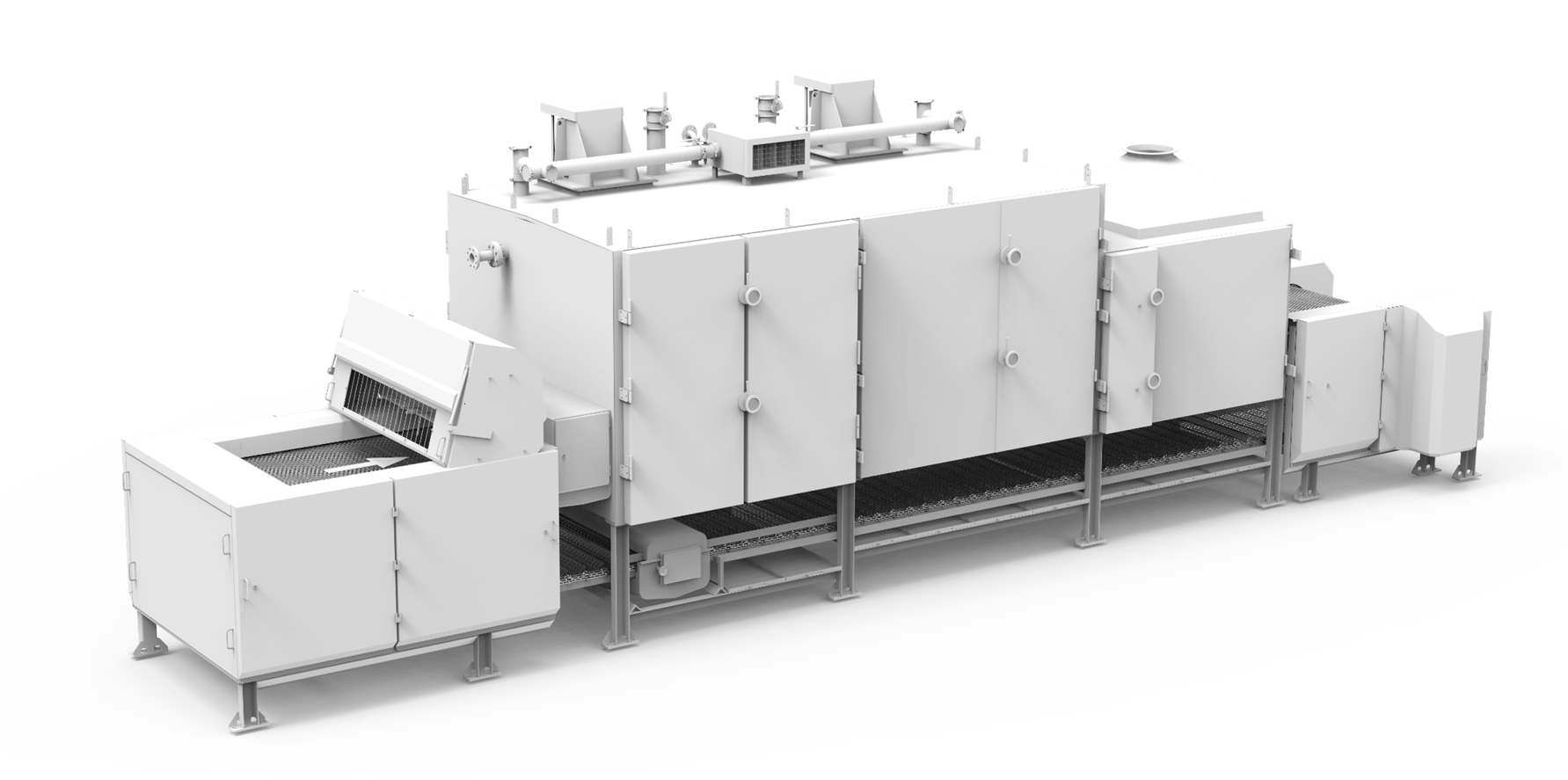

Band dryers

COMESSA offers a full range of BAND DRYERS to meet your requirements in thermal processing of divided solids.

Band dryer principle

Band dryer is composed of one perforated conveyor supporting a layer of product, passed through by process gas.

Dryer is constituted by several modular sections with independent heating and air circulation systems. Process gas is blown whether downward or upward or in a combined arrangement in order to improve homogeneity of treatment.

Cooling section can be foreseen after drying zone.

Band dryer can be fitted with accessories (feeder, spreader, cleaning devices, etc.).

It is the most appropriate equipment for fragile, sticky, pasty products or products requiring long and accurate residence time.

Advantages of this technology

- Energy saving due to gas recycling

- Highly homogeneous treatment

- Adjustment of temperature, gas velocity and direction in each section

- Multiple processing in one single equipment

- Versatility of processes and applications

- Accurate adjustment of residence time

- Possibility to add accessories for mechanical action on product

Main processes

- Drying

- Calcining

- Cooling

- Cooking

- Toasting

- Dehydration

- Etc.

Main applications

Extrudates, beads, granules, pastes, pet food, sliced vegetables, flakes, rubber crumbs, catalysts, etc.

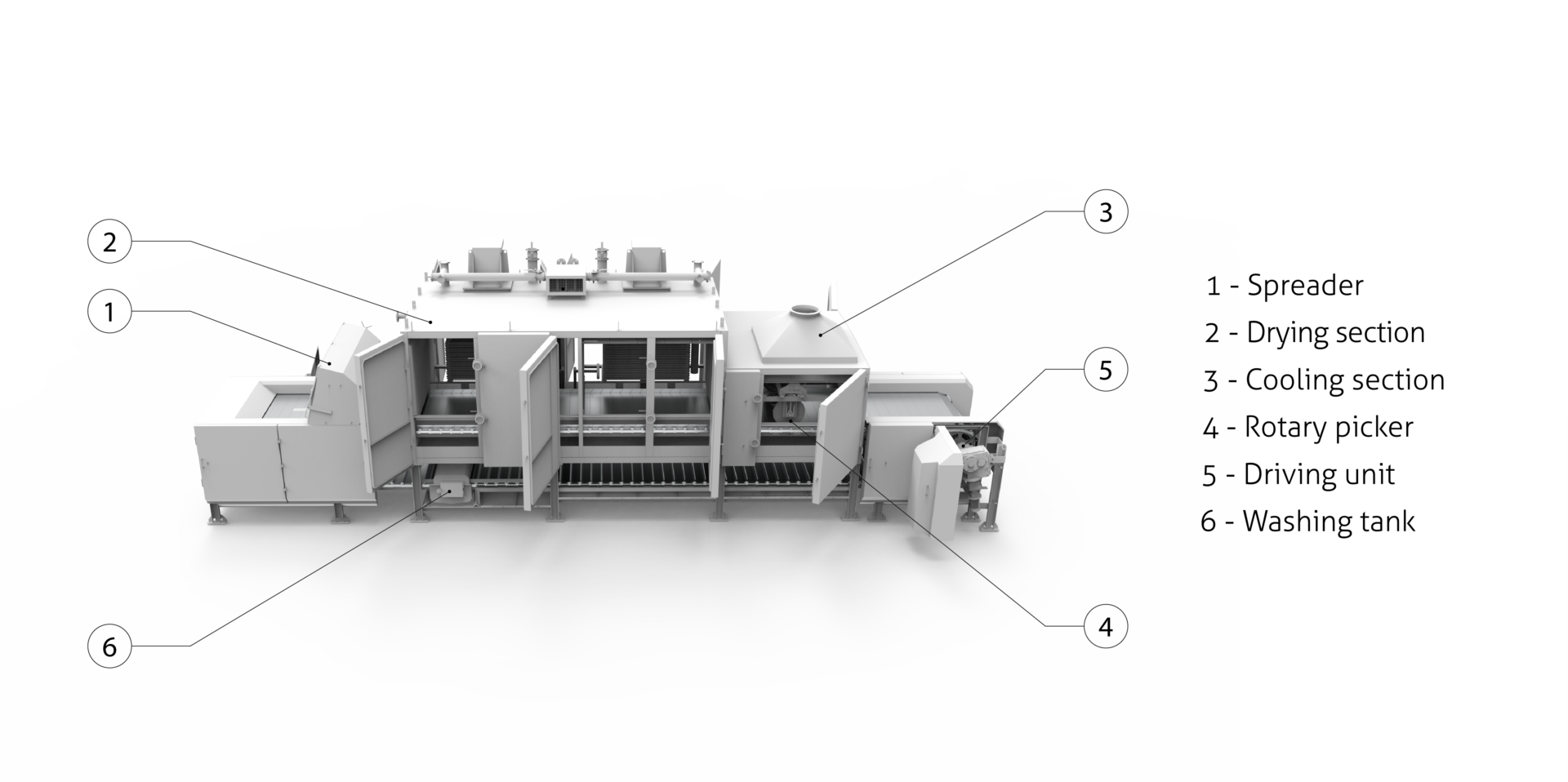

Typical band dryer arrangement

Depending on the customer’s requirements and application, COMESSA can supply a complete process unit including auxiliary equipment such as: heating modes (electric, gas, steam), conveyor types (continuous perforated belt, articulated perforated plates, etc.) and accessories (distributor, cleaning device, etc.).

ASK FOR OUR BROCHURE

Ask for our technical equipment leaflets

GERMAN, SPANISH versions available upon request through our contact form.

Test laboratory

COMESSA has its own test laboratory covering more than 1,200 m² offering the possibility of carrying out feasibility tests and semi-industrial tests, for all its technologies.