AccueilHome > Fluidized beds

Fluidized beds

COMESSA offers a full range of FLUIDIZED BEDS technologies to meet your requirements in thermal processing of divided solids.

Fluidization (vibrating fluid bed, internals).

Example of fluidization.

Principle of fluidization

Fluidization confers to a divided solid the properties of a fluid.

Products with a wide particle size distribution or including large particles, cannot be processed in a static fluidization equipment.

Static fluid beds (with or without heat exchangers)

The fluidization is a state of dynamic balance of a divided solid in an ascending moving gas.

Such method of bringing in contact a solid with a gas, allows high mass and heat transfers.

Mechanical energy transferred by gas to the particles is low enough to prevent attrition.

Crystals for instance will remain bright and will keep sharp edges.

Advantages of this technology

- Controlled residence time allowing uniform treatment

- Low attrition of particles

- High thermal efficiency

- Preservation of physical and biological properties of fragile products

- Simple and robust equipment (no mechanical device)

- Low maintenance

- Easy cleaning

- Multiple processing in one single equipment

- Possibility to process under controlled atmosphere in a closed loop (i.e. nitrogen, hydrogen, etc.)

- Adjustable fines removal ratio

Main processes

- Drying

- Cooling

- Calcining

- Reactions

- Toasting

- Reduction

- Dehydration

- Solvent removal

- Etc.

Advantages of this technology

- Controlled residence time allowing uniform treatment

- Low attrition of particles

- High thermal efficiency

- Preservation of physical and biological properties of fragile products

- Simple and robust equipment (no mechanical device)

- Low maintenance

- Easy cleaning

- Multiple processing in one single equipment (drying, thermal treatment, cooling)

- Possibility to process under controlled atmosphere in a closed loop (nitrogen, hydrogen, low O₂/CO₂ air, etc.)

- Adjustable fines removal ratio

Main processes

- Drying

- Cooling

- Calcining

- Reactions

- Toasting

- Reduction

- Dehydration

- Solvent removal

- Etc.

Main applications

All kinds of powders, crystals, beads, granules, pellets for all industries (chemicals, agri-food, minerals, etc.).

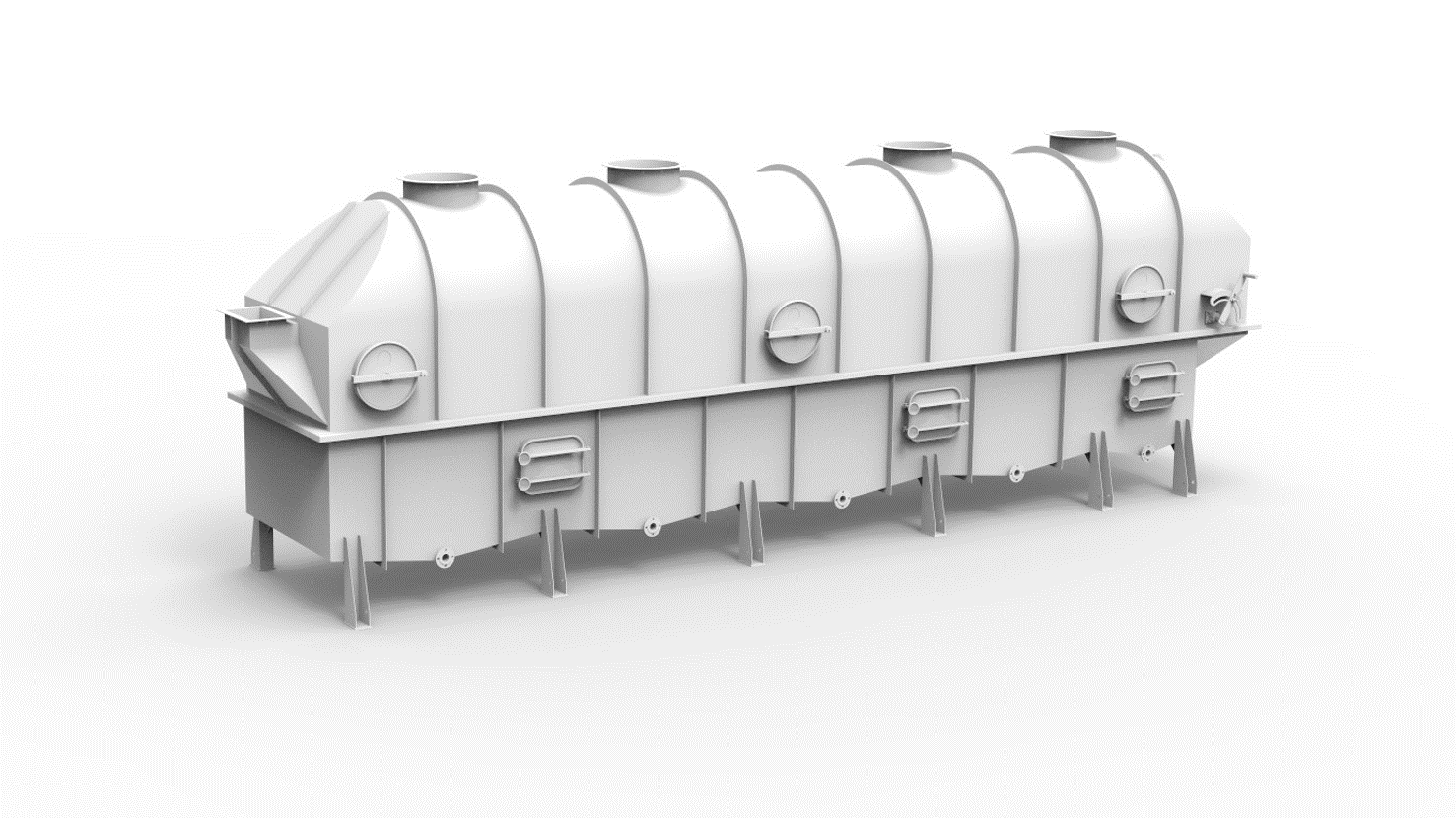

Static fluid bed

The standard static fluidized bed is composed of a plenum for gas injection, a fluidization plate for a homogeneous

air distribution and a hood for product conveying and gas exhaust.

Learn more

Fluidization plate may be from different types: perforated sheets, porous metal, oriented air jet, nozzles or other type, depending on processes and applications.

The plenum chamber is generally subdivided into several sections to provide the optimum fluidization velocity at each stage of processing. The temperature of the processing gas can be adapted for each plenum section. Final section can be a cooling zone.

The processed product is discharged by overflowing an adjustable weir (typically from 0 to 300 mm).

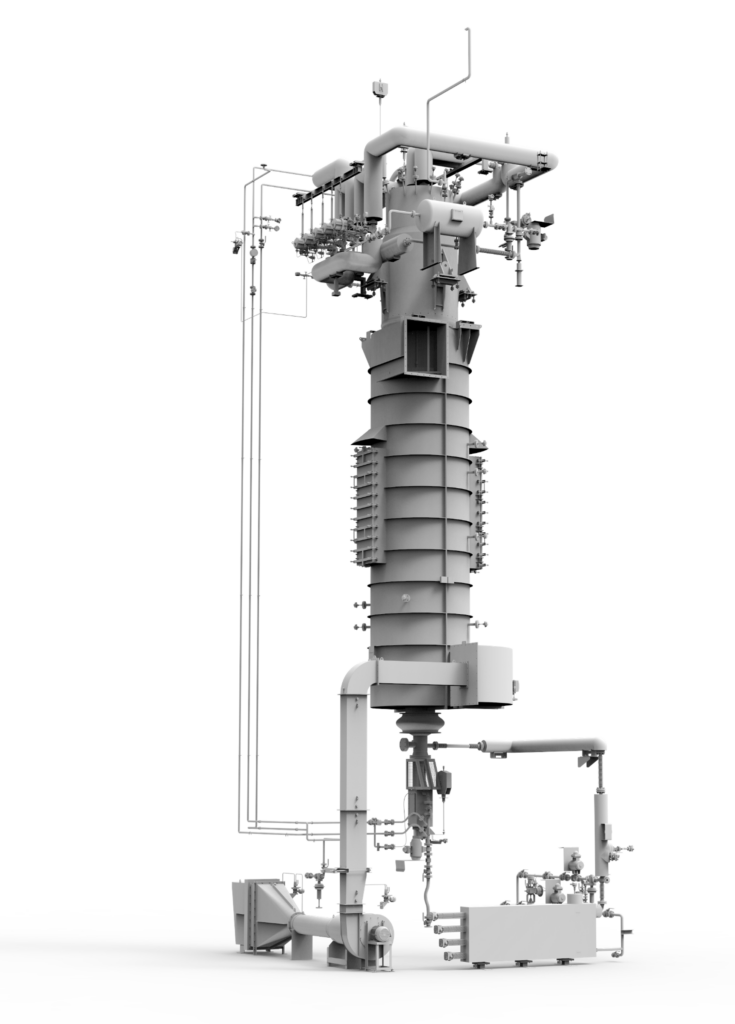

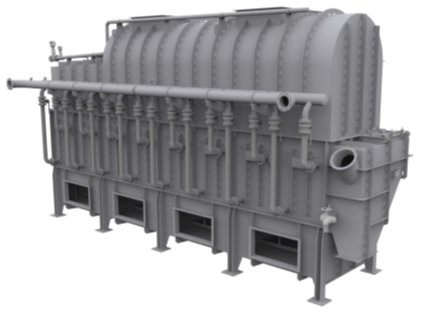

Static fluid bed with immersed heat exchangers

For fine powders (or heat sensitive products) thermal supply brought by fluidization gas is very low due to low gas velocity (or low gas temperature). Therefore, the fluidized bed area would be quite important.

Learn more

Addition of internal immersed heat exchangers will reduce significantly the size of the equipment as most of the thermal balance will be achieved by conduction through these exchangers.

Typical height of product layer will be between 600 to 2000 mm in order to allow integration of the immersed heat exchangers. Depending on application, different types of exchangers are available (bundle of tubes, dimpled plates, etc.).

Depending on application, different types of exchangers are available (bundle of tubes, dimpled plates, etc.).

-

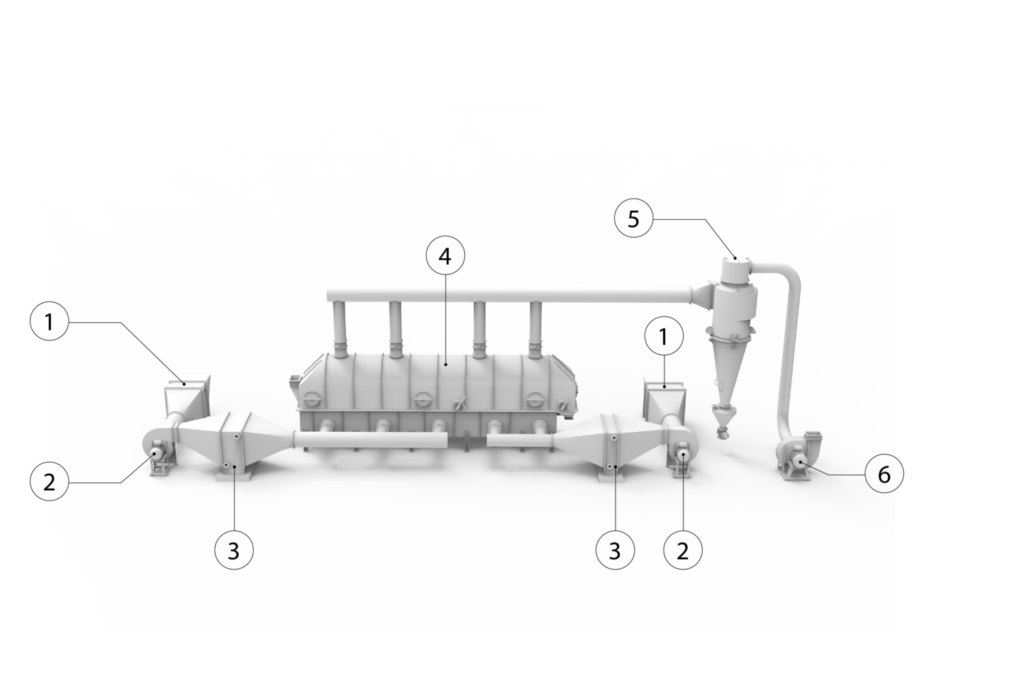

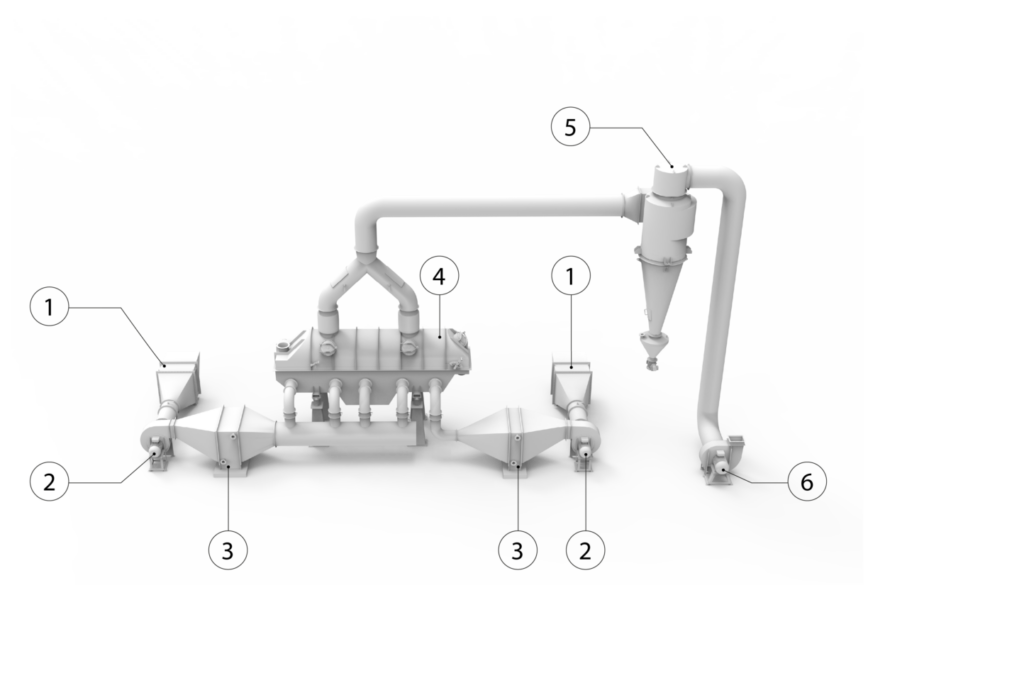

Air filter(s)

-

Blower(s)

-

Heat exchanger(s)

-

Static fluidized Bed

-

Dedusting unit

-

Exhauster

Complete process unit

Depending on customer’s requirements and applications, COMESSA can provide a complete process unit including ancillaries equipment such as: air preparation assemblies, dedusting units (cyclone, filter, scrubber…), instrumentation, automation, etc.

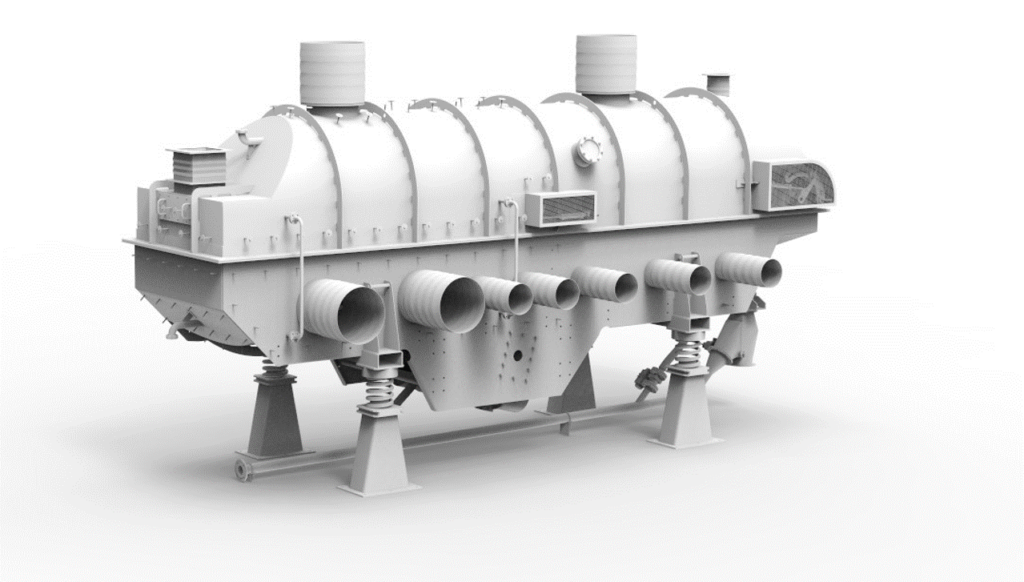

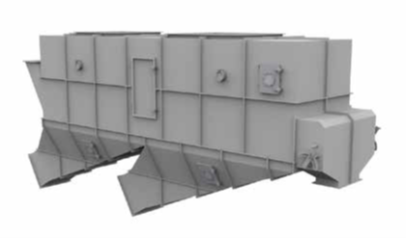

Vibrating fluid beds

It is the same for products discharged from centrifuges which are sticky or include lumps and which will not permit treatment by direct fluidization.

COMESSA developed the vibrating fluidized bed to solve most of these delicate drying problems.

In such case, vibration insures a better fluidization and allows transport of largest particles or lumps.

Advantages of this technology

- Handling of sticky products (from centrifuges or filters)

- Adapted to products with a wide particle size distribution

- Homogeneous product processing

- Low attrition

- High evaporation rate

- Compact footprint and simplified layout

- Easy adjustment (residence time, temperature, airflows)

- Multiple processing in one single equipment

- Adjustable fines removal ratio

Main processes

- Drying

- Cooling

- Calcining

- Reactions

- Toasting

- Dehydration

- Solvent removal

- Etc.

Main applications

All kinds of powders, crystals, beads, granules, pellets for all industries (chemicals, agri-food, minerals, etc.).

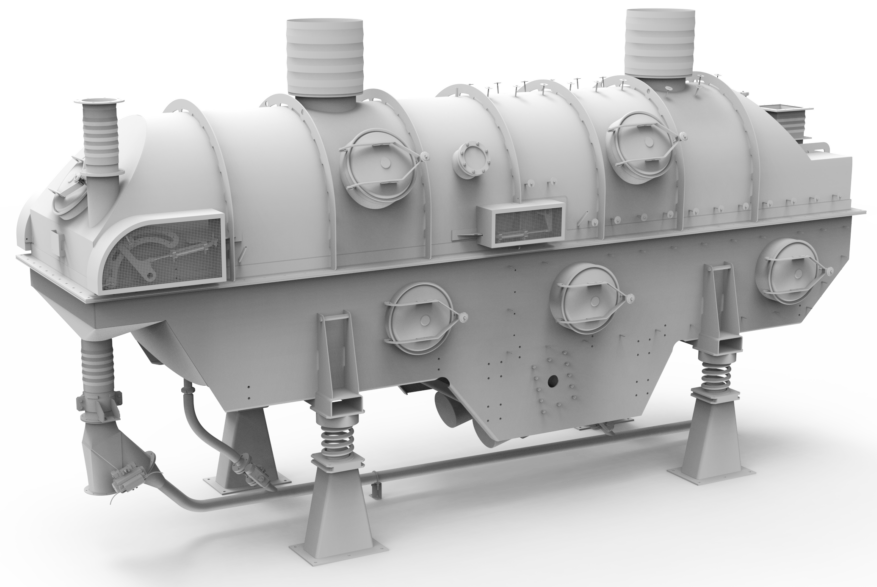

Vibrations generated by motovibrators

Fluid bed is supported by 4 helical springs.

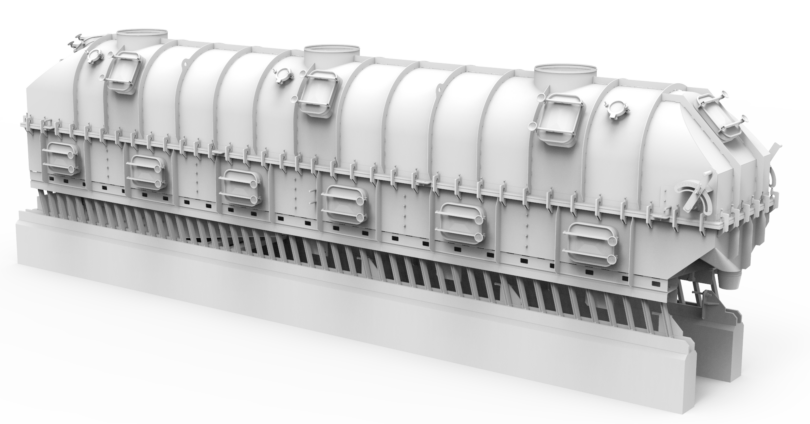

Vibrations generated by an exciter

Vibrating fluid bed is supported by 2 rows of leaf springs.

-

Air filter(s)

-

Blower(s)

-

Heat exchanger(s)

-

Vibrating fluidized Bed

-

Dedusting unit

-

Exhauster

Complete process unit

Depending on customer’s requirements and applications, COMESSA can provide a complete process unit including ancillaries equipment such as: air preparation assemblies, dedusting units (cyclone, filter, scrubber…), instrumentation, automation, etc.

ASK FOR OUR BROCHURE

Ask for our technical equipment leaflets

GERMAN, SPANISH versions available upon request through our contact form.

Test laboratory

COMESSA has its own test laboratory covering more than 1,200 m² offering the possibility of carrying out feasibility tests and semi-industrial tests, for all its technologies.