AccueilHome > Rotary tubes

Rotary tubes

COMESSA offers a full range of

ROTARY TUBES to meet your requirements

in thermal processing of divided solids.

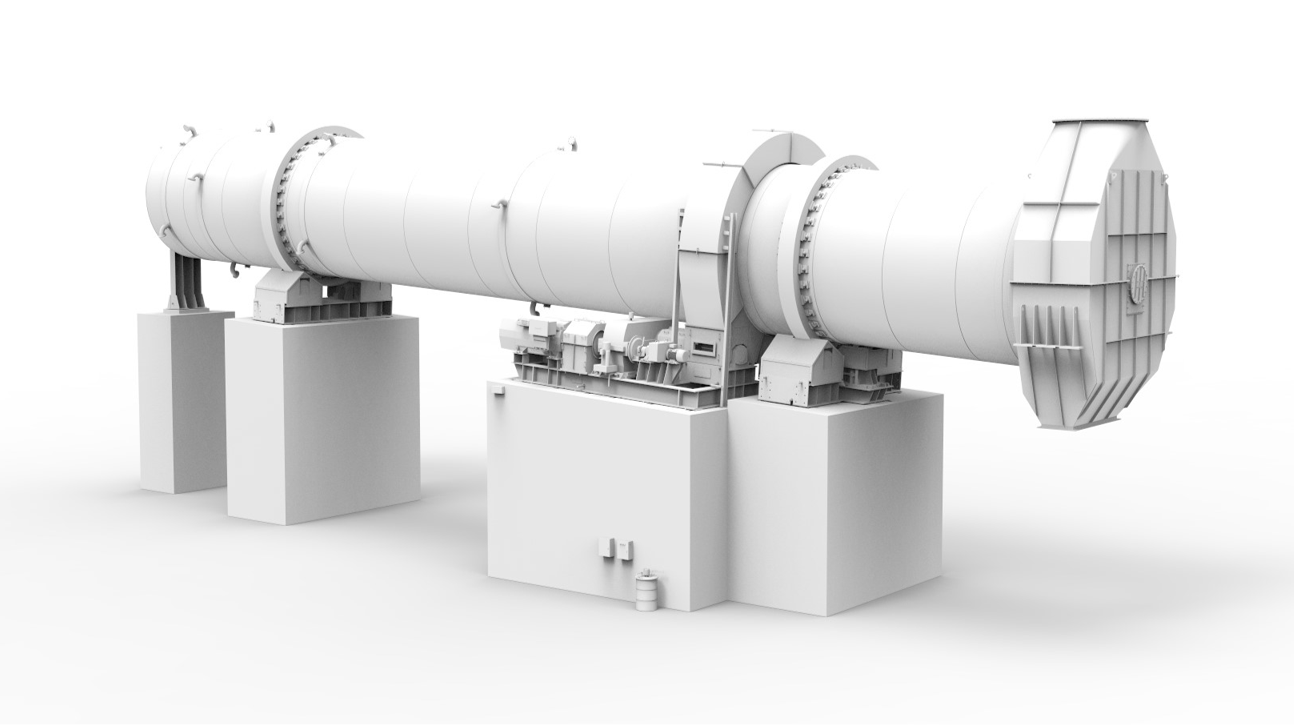

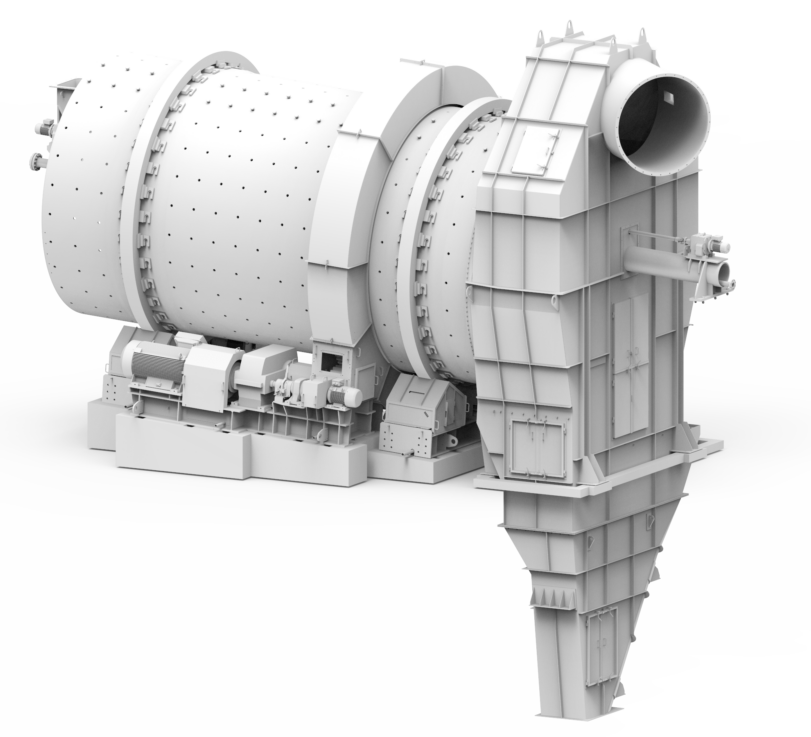

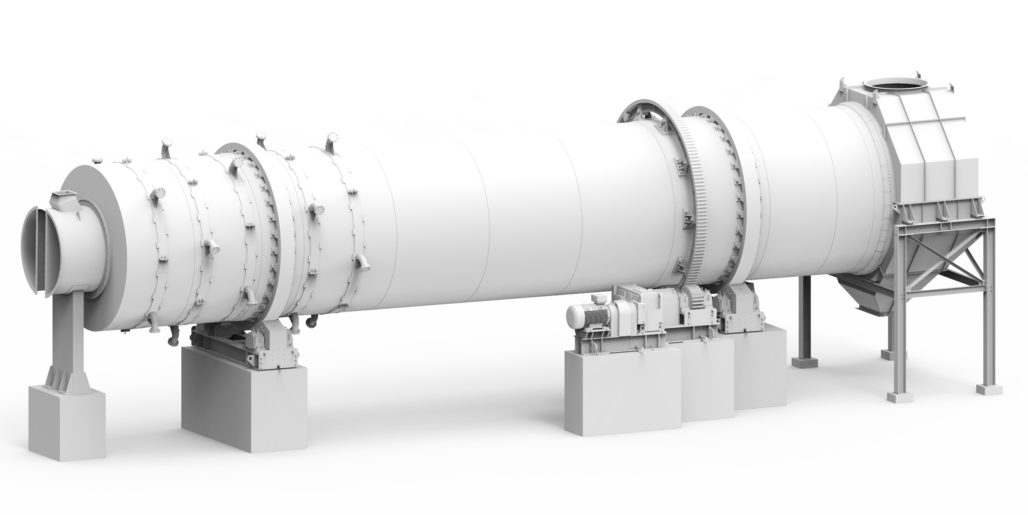

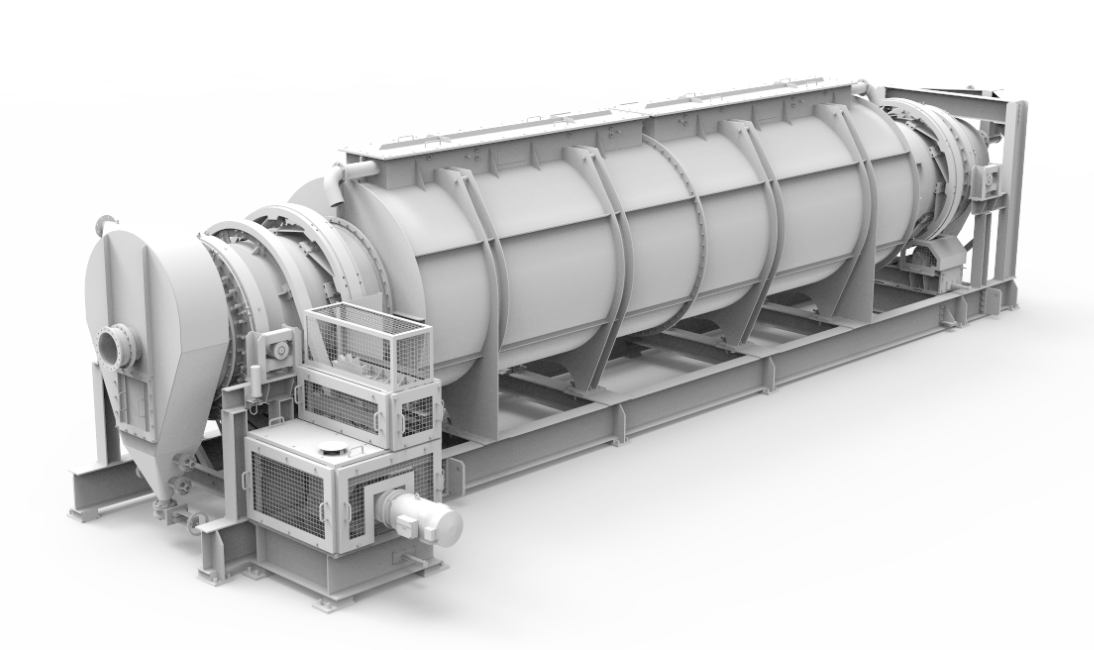

Rotary tubes principle

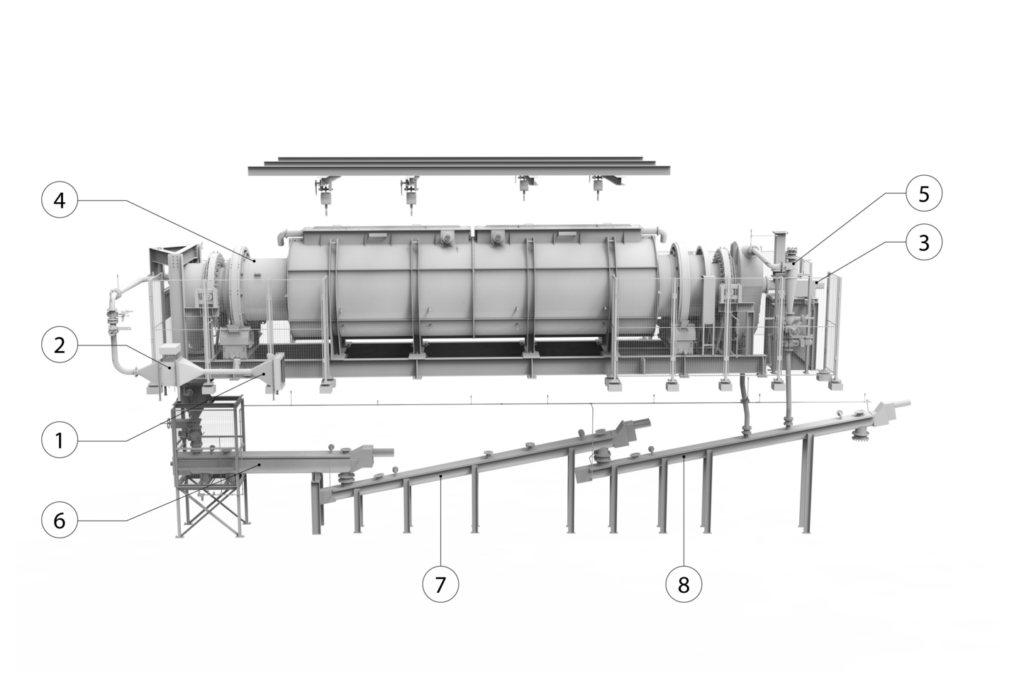

Rotary tube is composed of one slightly sloped shell, fitted with two riding rings supported by four rollers and driven by a chain drive or a girth gear assembly.

Internal spiral flights and lifters allow conveying of product from the inlet to the outlet of the shell and insure a proper and efficient thermal exchange between product and process gas.

Rotary tubes can be used in various configurations : co-current, counter current, indirectly heated through the shell or by means of internal tubular exchanger.

They are dedicated to a large range of divided solids from fine powders to large particles.

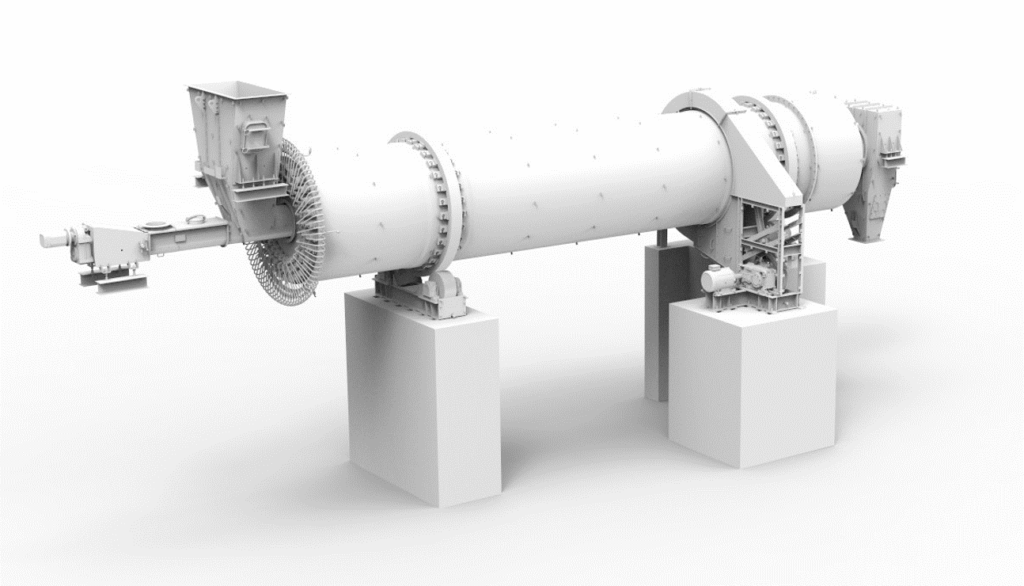

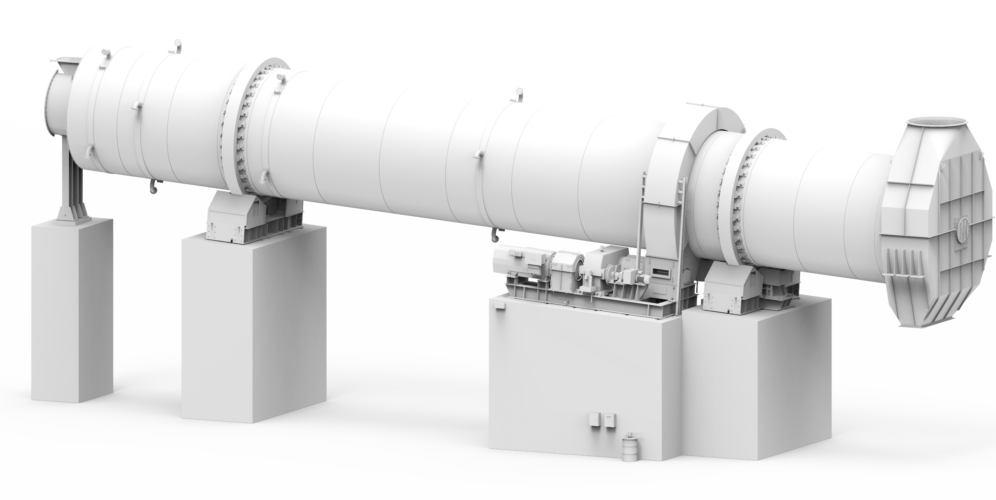

Direct rotary tubes

- Dryer

- Cooler

- Calciner

- Combined dryer & cooler

Heat exchange is done by contact between product and gas. Depending on the products to be treated and the process requirements, gases and product flow either co-current or counter-currently.

For all dryers and coolers, internal lifters are specifically designed for each application to optimise contact between air and product, and then improve thermal efficiency.

Rotary dryer,

cooler

and calciner

This type of equipment is specifically used for drying, cooling, or calcining.

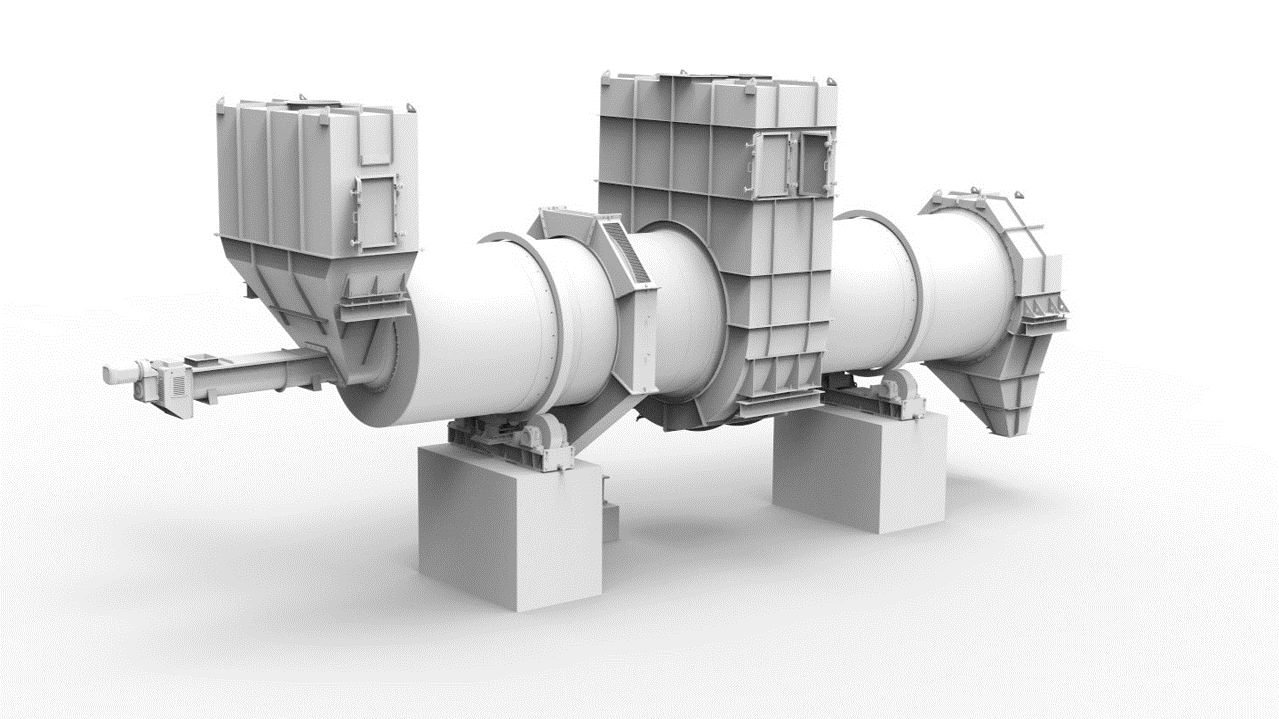

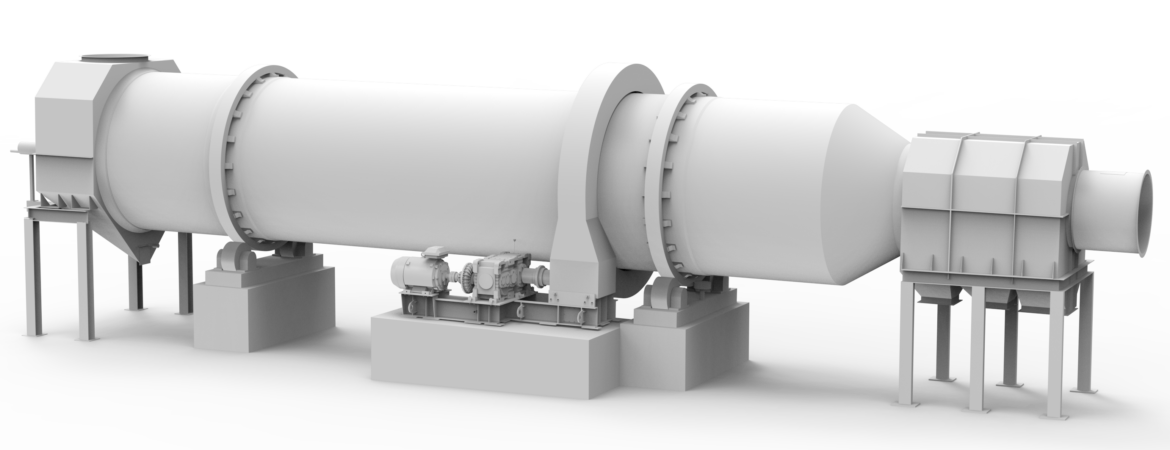

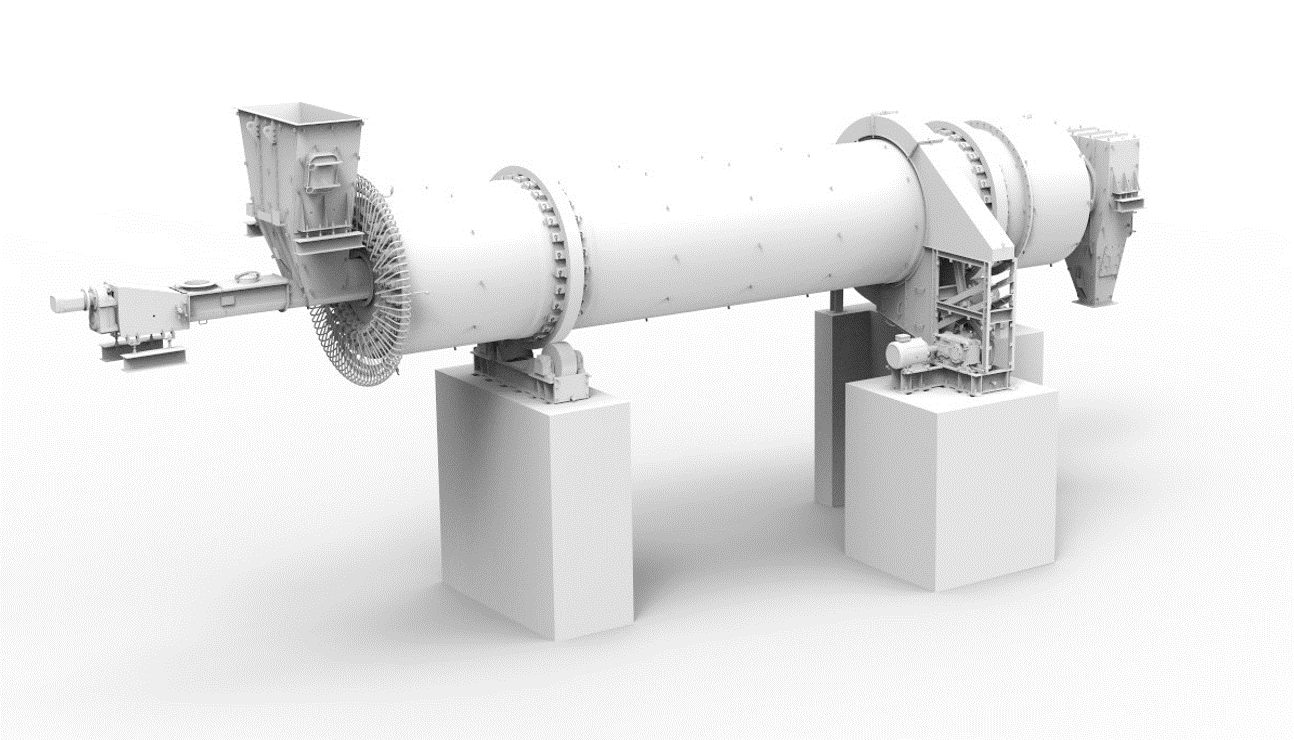

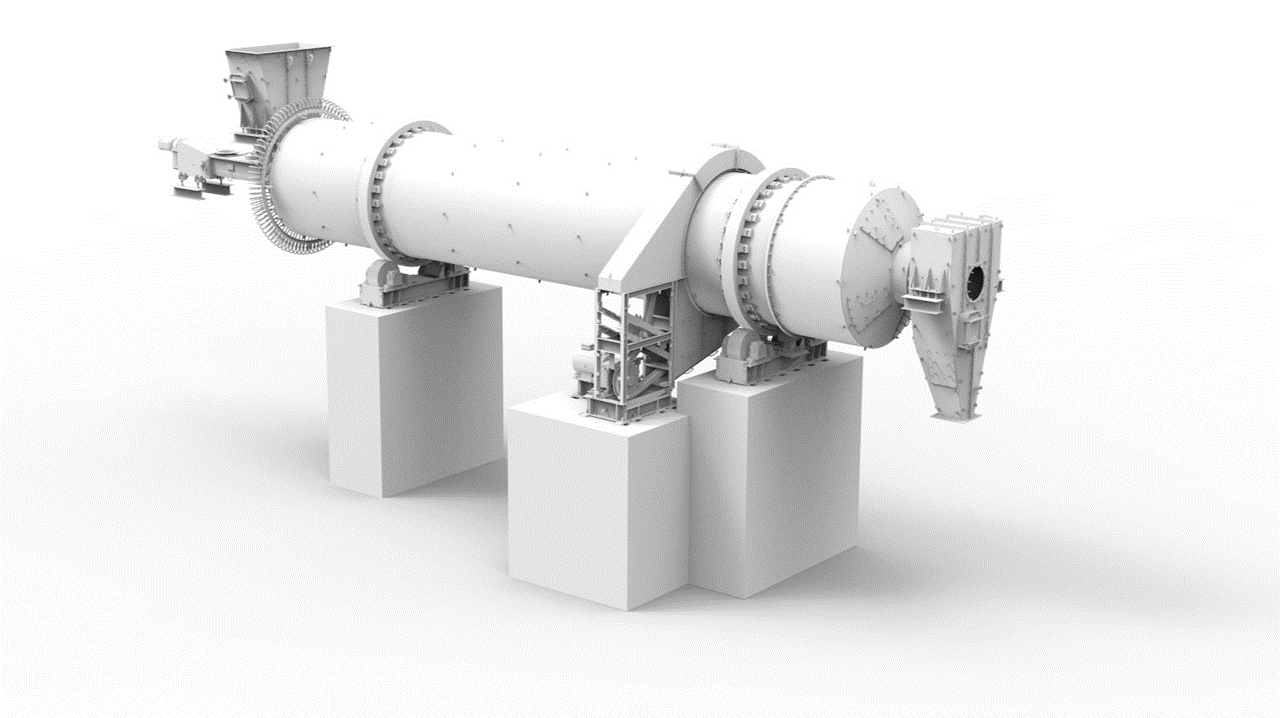

Combined rotary

dryer & cooler

This kind of convective rotary tube is composed of two separate sections (drying & cooling).

Learn more

With intermediate transfer box

Independent sections separated by a partition allowing:

- Product transfer through this intermediate partition;

- Injection or exhaust of process air through this partition.

Drying air is co-currently, cooling air is counter-currently and the total air is extracted by the center of the drum. A special product transfer device is also foreseen for the conveying of the product from the drying zone to the cooling zone (drying process can alternatively be in counter-currently configuration as well).

With central pipe

No internal separation between drying and cooling zones. Cooling air is re-used for drying after getting mixed with additional make-up air injected trough central pipe.

This kind of combined dryer-cooler is typically suitable for sugar, but also for some other crystals and sand.

Rotary

granulator

This kind of equipment is specifically used for granulation of fertilizers.

Rotary

coater/polisher

This kind of equipment is specifically used for final treatment of granulated or compacted fertilizers.

Shake-out

drum

This kind of equipment is provided to separate castings and sand.

Castings and sand can be cooled down by the dedusting air flowing counter-currently or by adequate water spraying.

Advantages of this technology

- Handling of heterogeneous products with a large range of shape, size and density

- Proven technology

- Heavy duty

- High drying / calcining temperature

- High flexibility

- High evaporation

- Large capacity

Main processes

- Drying

- Cooling

- Calcining

- Granulation

- Coating

- Polishing

- Shake-out

- Etc.

Main applications

All kind of powders, crystals, beads, granules, fibers, cakes, chips, for all industries (chemicals, fertilizers, food, minerals, etc.)

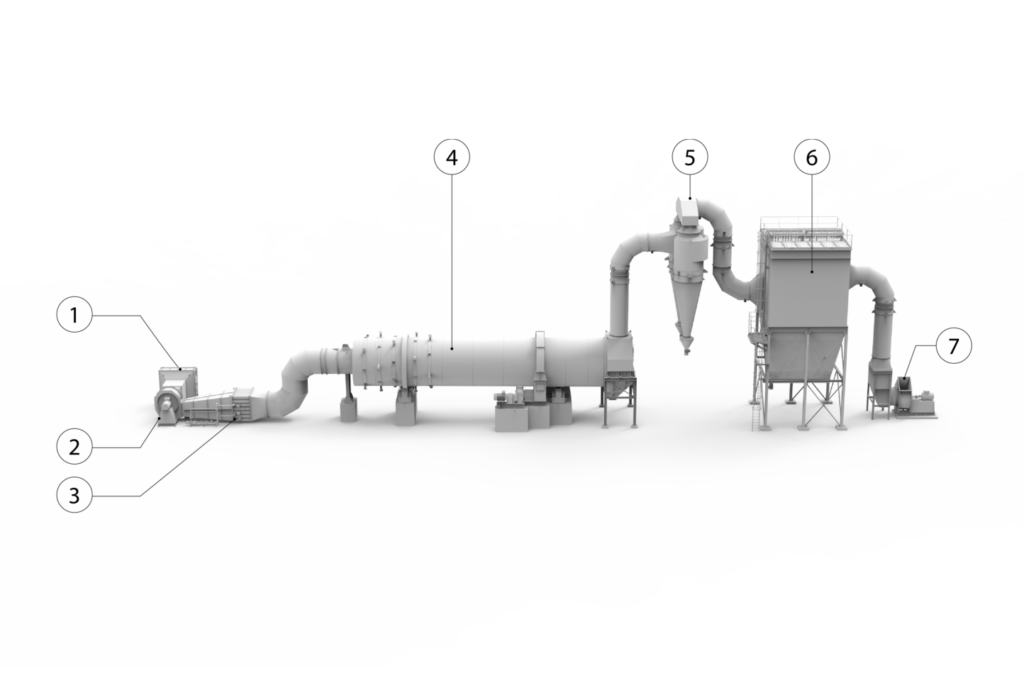

-

Air filter(s)

-

Blower

-

Air heater

-

Rotary tube

-

Cyclone(s)

-

Bag filter

-

Exhauster

Complete process unit

(e.g. direct rotary tube dryer)

Depending on customer’s requirements and applications, COMESSA can provide a complete process unit including ancillary equipment such as: air preparation assemblies, dedusting units (cyclone, filter, scrubber…), instrumentation, automation, etc.

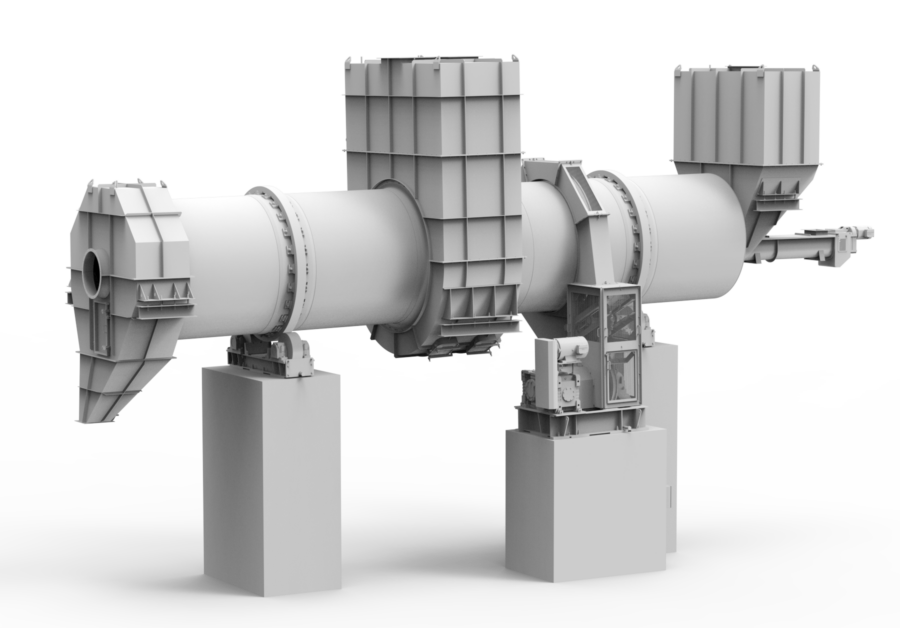

Indirect rotary tubes

- Solvent removal

- Dehydration

- Cooler

This kind of equipment enables drying, cooling or calcining operations while minimizing stripping gas quantity.

Rotary tube

heated through the wall

- Drying

- Calcining

- Gas-solid reactions

- Reduction

Learn more

Types of heating mantels:

- Electrical coils

- Gas burners

- Hot gas

Energy is brought through the wall of the shell.

Shell can be built in refractory steel or special alloy.

This kind of technology is used for drying, thermal treatment and calcination, up to 950 °C.

We can control the internal atmosphere and operate under air, N₂, CO₂, H₂, etc. Rotating seals are specially designed for gas and dust tight operations.

This technology is particularly suitable for processing of catalysts and battery active materials.

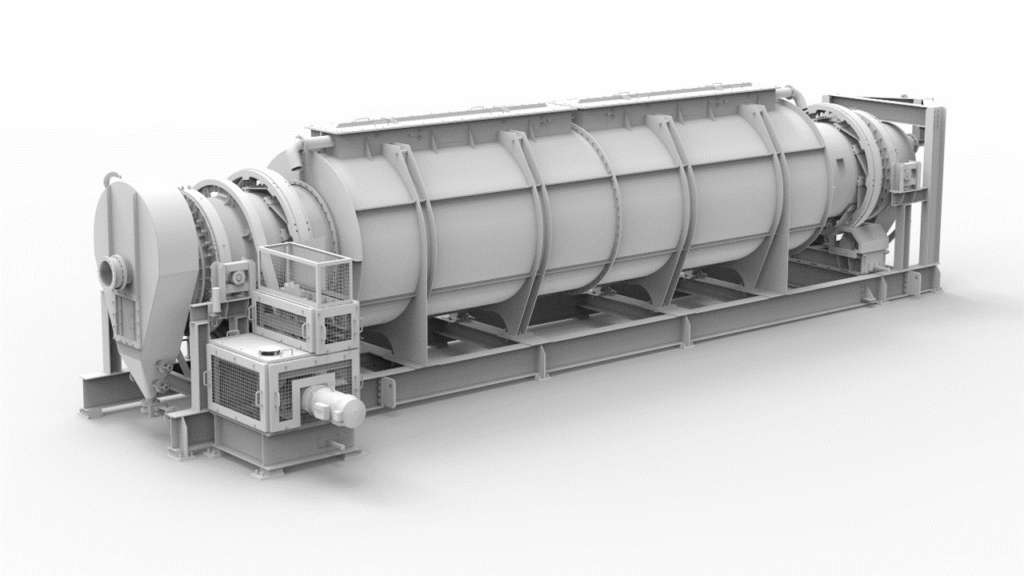

Rotary tubes with heat exchanger

“steam tube dryers”

- Drying

- Solvent removal

- Dehydration

Learn more

Rotary tube is fitted with a heat exchanger composed of bundle of tubes integrated inside the shell.

This technology is typically applied for thermo-sensitive products or for desolvation. Stripping gas flow is minimized.

This equipment can be also operated under controlled atmosphere.

We have experience with steam up to 50 bars.

Rotary tubes with built-in

air or water exchanger

- Cooling

Learn more

Air or water coolers, are dedicated to very fine or highly hygroscopic products. Sensitive heat of product can be easily recovered for other processes.

Advantages of this technology

- Minimize stripping gas flow

- High thermal efficiency

- Suitable for fine products

- Suitable for controlled atmosphere operations

- Proven technology

- Heavy duty

- Suitable for high temperatures

- High flexibility

- High evaporation rate

- Large capacity

Main processes

- Drying

- Cooling

- Calcining

- Gas-solid reactions

- Reduction

- Dehydration

- Solvent removal

- Etc.

Main applications

All kind of powders, crystals, beads, granules, fibers, cakes, chips, for all industries (chemicals, food, minerals, etc.).

-

Air filter(s)

-

Air heater

-

Feeding screw

-

Rotary tube

-

Cyclone

-

Cooling screw

-

Conveying screw

-

Conveying screw

Complete process unit

(e.g. indirect rotary dryer)

Depending on customer’s requirements and applications, COMESSA can provide a complete process unit including ancillary equipment such as: air preparation assemblies, dedusting units (cyclone, filter, scrubber…), instrumentation, automation, etc.

ASK FOR OUR BROCHURE

Ask for our technical equipment leaflets

GERMAN, SPANISH versions available upon request through our contact form.

Test laboratory

COMESSA has its own test laboratory covering more than 1,200 m² offering the possibility of carrying out feasibility tests and semi-industrial tests, for all its technologies.