AccueilHome > Environment / Recycling

Since the 1950s, COMESSA has specialized in the design, manufacturing, erection and commissioning of a wide range of equipment for drying, calcining and cooling adapted to the requirements of its customers, in environment and recycling fields.

More stringent requirements in terms of respect for the environment have resulted in COMESSA developing and supplying a number of plants for processing of recycled products and waste.

Services we provide range from supplying individual equipment to complete plants, including:

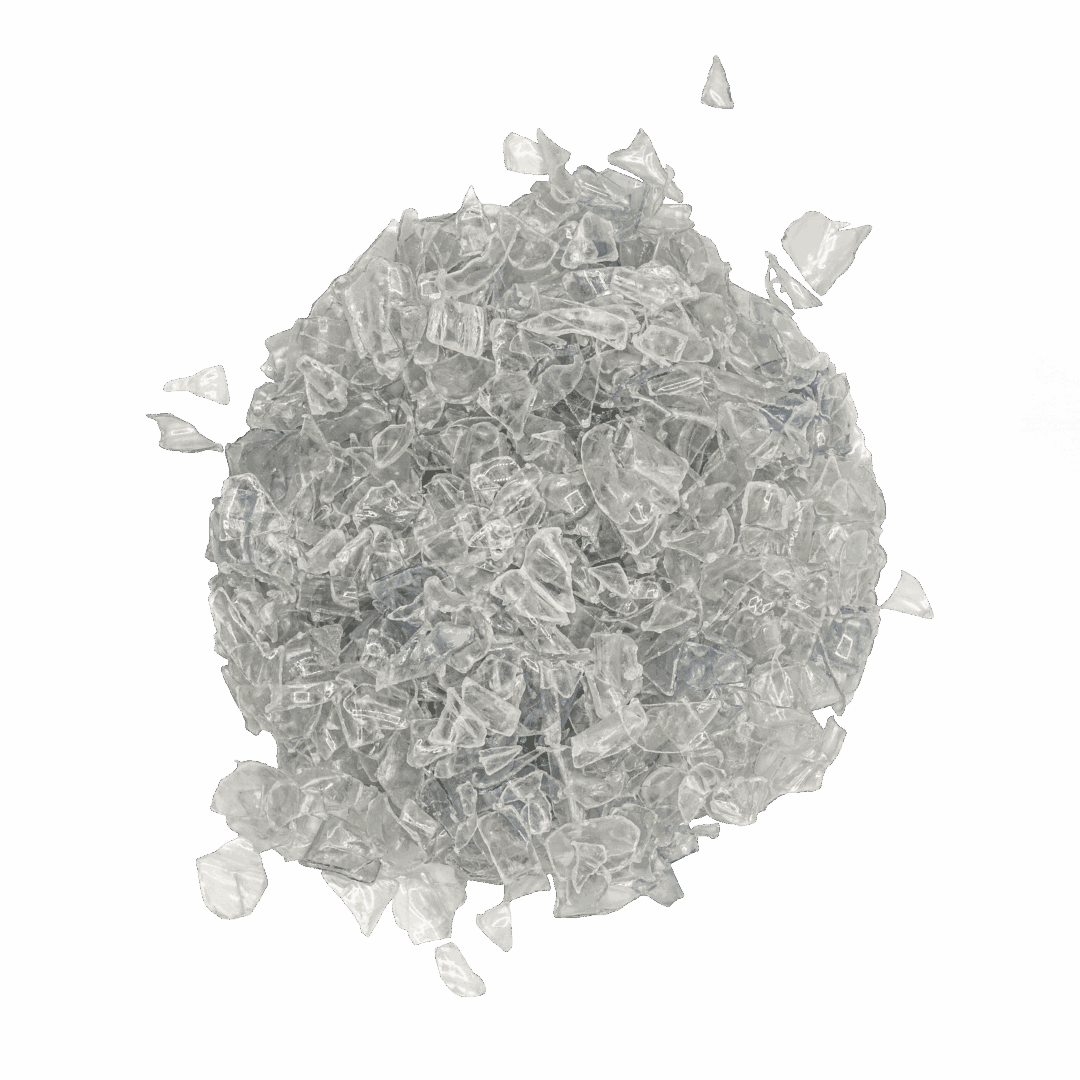

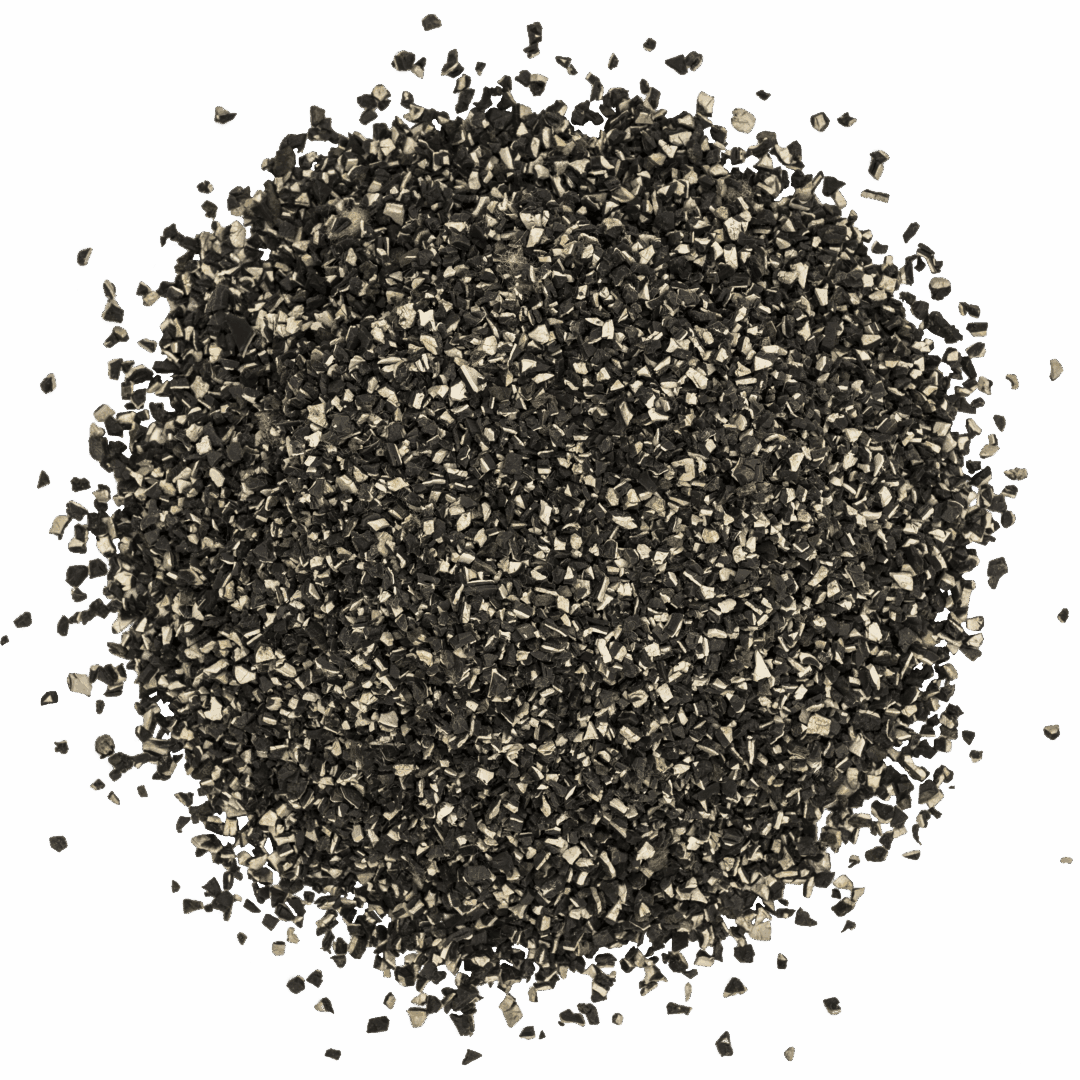

Depending on the product to be treated, COMESSA offers a number of solutions:

Choosing the most appropriate equipment depends on the nature and type of product to be processed.

To validate solutions, COMESSA has a its own test laboratory in which all the technologies can be tested.

If the product you need to process is not in our list, or if you have particular constraints, we invite you to contact us. We remain at your disposal, should you need any assistance in defining your technological choices.

ABSE-IPSB, De Smet, Eras, SNC-Lavalin…

Aquafin, Caremag, Degremont, DuPont, Exelgom, Geteba, Ipaq, Kazzinc, Mitsubishi Polyester Film, Pechiney, Renault, Rockwool, Russian Chrome, Sadaci, Seghers, Tioxyde (groupe Huntsman), Trédi (groupe Séché), Valdi (groupe Eramet), Veolia Water…

Example of fluidization.

GERMAN, SPANISH versions available upon request through our contact form.

COMESSA has its own test laboratory covering more than 1,200 m² offering the possibility of carrying out feasibility tests and semi-industrial tests, for all its technologies.

To provide the best experiences, we use technologies such as cookies to store and/or access device information. Consent to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent may negatively impact certain features and functions.

Our references