AccueilHome > High temperature fluidized beds and rotary tubes (up to 950 °C)

High temperature

applications

COMESSA offers a full range of HIGH TEMPERATURE technologies to meet your requirements in thermal processing of divided solids.

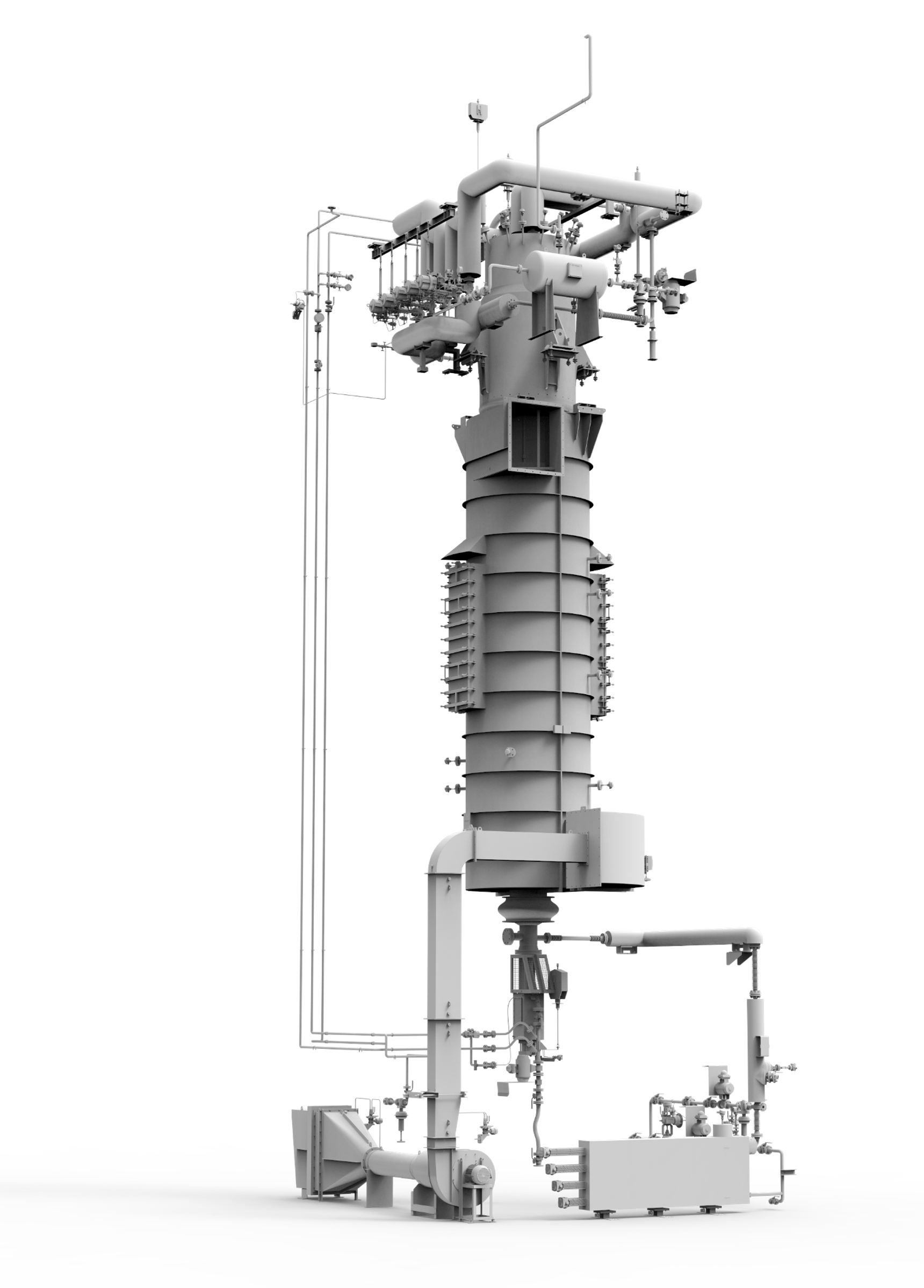

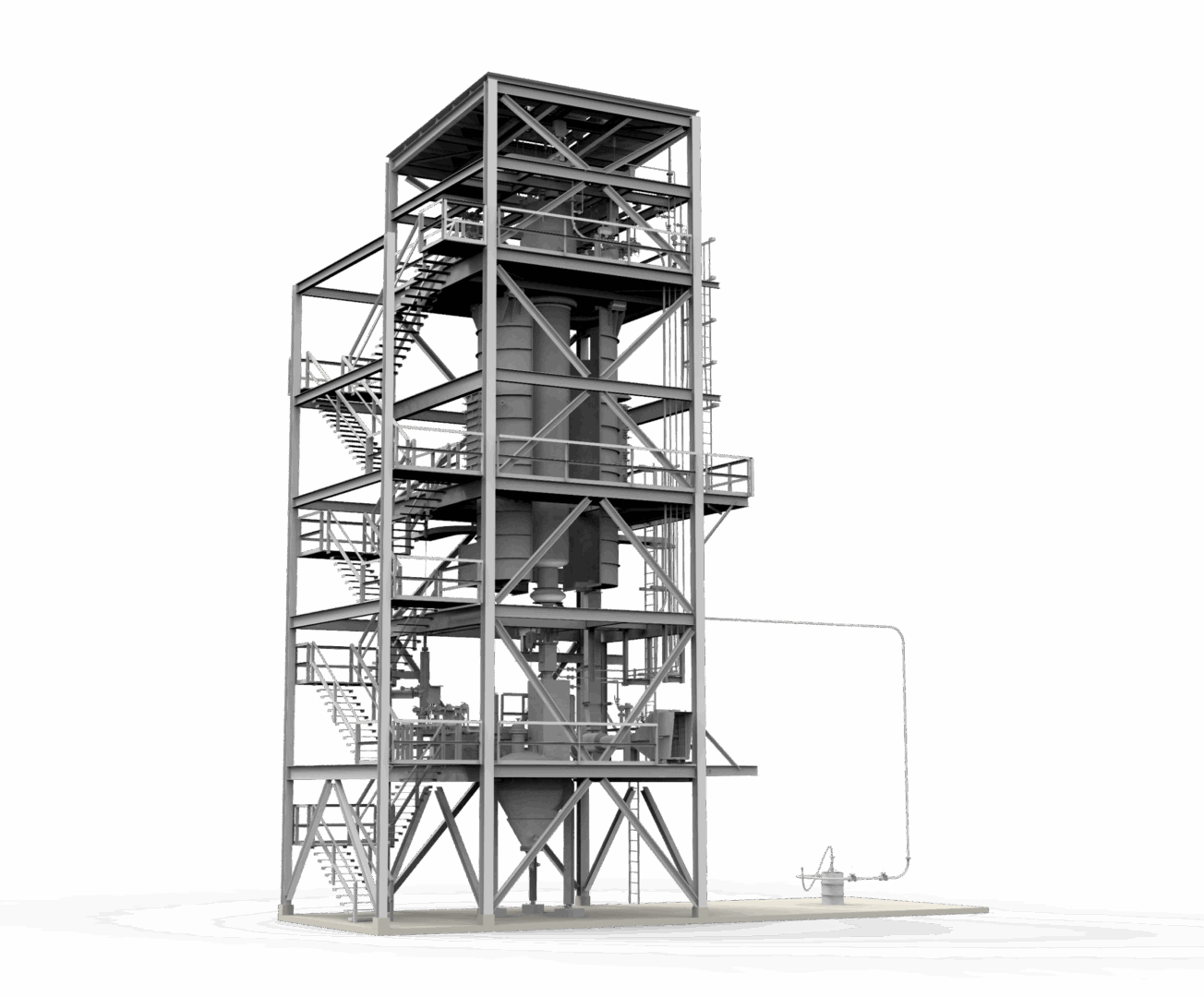

High temperature fluid beds

In complement to standard static or vibrating fluidized beds, suitable to work up to 400°C, COMESSA designs also high temperature fluid beds up to 950°C.

This batch fluidized bed is constituted by a metallic cylindrical reactor heated through the wall, allowing an internal controlled atmosphere, independent from heating load. The retort can be externally heated by radiation with electrical coils or by hot gases. The fluidization gas is homogeneously distributed by a special conical plate, allowing discharge of treated product through a central high temperature valve.

Exhaust gases are cleaned by a filter made of sintered metal cartridges. Depending on the application and

characteristics of the product, the filter can be externalized and an agitator can be added in the layer of product.

Fluidization will generate an important stirring between gas and product and therefore a very homogeneous treatment.

Precise temperature and process cycle can be fully automated.

This kind of equipment is typically dedicated to the treatment of catalysts, even with particles below 30 microns. Direct heating or continuous processes can be alternatively proposed.

Advantages of this technology

- Controlled residence time allowing uniform treatment

- Low attrition of particles

- High thermal efficiency

- Preservation of physical and biological properties of fragile products

- Simple and robust equipment (no mechanical device)

- Low maintenance

- Easy cleaning

- Multiple processing in one single equipment

- Possibility to process under controlled atmosphere in a closed loop (i.e. nitrogen, hydrogen, etc.)

- Adjustable fines removal ratio

Main processes

- Drying

- Cooling

- Calcining

- Reactions

- Toasting

- Reduction

- Dehydration

- Solvent removal

- Etc.

Advantages of this technology

- Highly uniform poduct treatment

- Operating under controlled atmosphere

- Accurate control of operating temperature profile

- Control of fluidization velocity

- Possibility to add an agitator

- Possibility to have internal filtration

- High degree of containment

Main processes

- Calcining

- Oxidation

- Activation

- Reduction

- Gas-solid reactions

- Regeneration

- Roasting

- Pyrolysis

- Etc.

Main applications

Catalysts activation or regeneration, metallic oxides reduction (Fe, Ni, Tu, Cr, Mo, Co), oxidation of metal salts, calcination of ores.

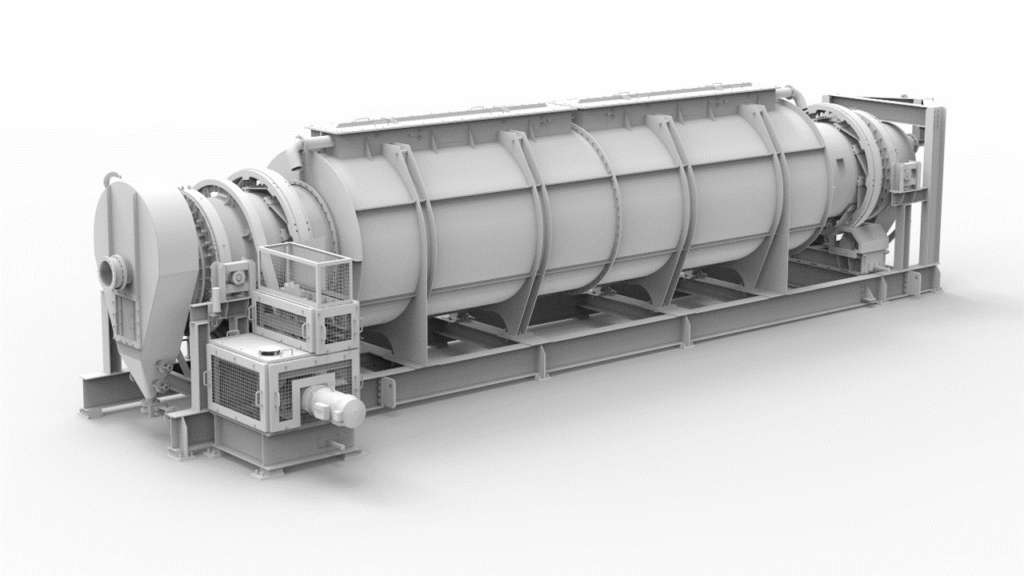

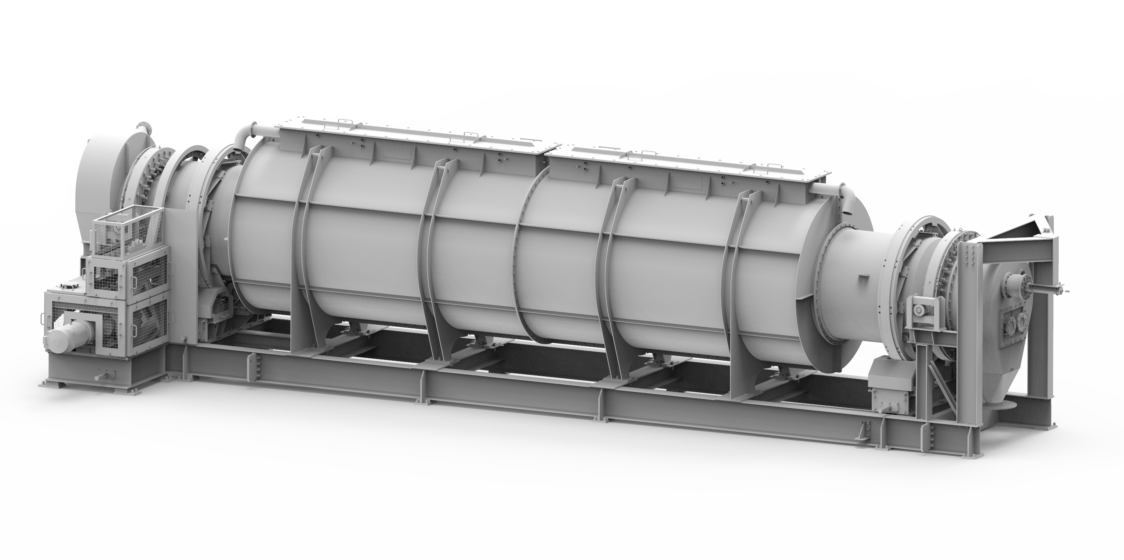

High temperature rotary tubes

In complement to standard rotary tubes, COMESSA designs also high temperature indirectly heated rotary tubes for thermal treatment up to 950°C.

Typical design is constituted by a metallic shell heated through the wall, allowing an internal controlled atmosphere, independent from heating load.

Thermal exchange is achieved by an external mantle, heating the shell by means of electrical coils, hot gases or direct flames burners.

Rotating shell can be made of special heat resistant alloys.

Design of internals allows a constant renewal of product in contact with the wall, insuring an optimal heat transfer.

Indirect heating reduces drastically stripping gas flow rate, allowing very low gas velocity suitable for treatment of finest products.

Rotary shell can be fitted with high performance seals, dedicated to controlled atmosphere processes or hazardous products.

Direct heated rotary tubes can be alternatively proposed.

Advantages of this technology

- Accurate control of temperature profile by separated heating zones

- Highly uniform product treatment

- Gas or dust tight design available

- Suitable for very fine products

- Possibility of controlled atmosphere

- High degree of containment

Main processes

- Calcining

- Oxidation

- Reduction

- Gas-solid reactions

- Regeneration

- Roasting

- Pyrolysis

- Etc.

Main applications

Catalysts and ores calcination, catalysts regeneration, treatment of molecular sieves / zeolites / activated carbons, oxidation or reduction of metal salts and oxides.

ASK FOR OUR BROCHURE

Ask for our technical equipment leaflets

GERMAN, SPANISH versions available upon request through our contact form.

Test laboratory

COMESSA has its own test laboratory covering more than 1,200 m² offering the possibility of carrying out feasibility tests and semi-industrial tests, for all its technologies.