AccueilHome > Pneumatic dryers (flash, rapid, cyclonic)

Pneumatic dryers

COMESSA offers a full range of PNEUMATIC DRYERS to meet your requirements in thermal processing of divided solids.

Flash dryers

Rapid dryers

Cyclonic dryers

Principle of pneumatic dryer

Flash drying works on the principle of pneumatic transport using hot air.

Wet product is introduced into a high velocity air stream through a special Venturi feeder.

Highly turbulent airflow generates an intense gas-solid thermal exchange and disaggregates the product.

This allows a rapid evaporation in a few seconds residence time.

Rapid drying process avoids overheating of product allowing the use of high temperature drying gases.

At dryer outlet, dried product is recovered by means of a gas-solid separator (cyclone, bag filter, etc.).

Partial recycling of dried product in wet material can be considered in case of sticky product.

This process is particularly suitable for fine products or filter cakes.

Advantages of this technology

- Simple and robust process

- High thermal efficiency

- Low maintenance

- Highly reactive process

- Easy and efficient control

- Reduced foot-print layout

- Processing of agglomerated products

Main processes

- Pre-drying

- Dehydration

- Drying

- Etc.

Main applications

Fine powders, filter cakes, fibers, sawdust, lightweight products for all industries (chemicals, food, minerals, etc.).

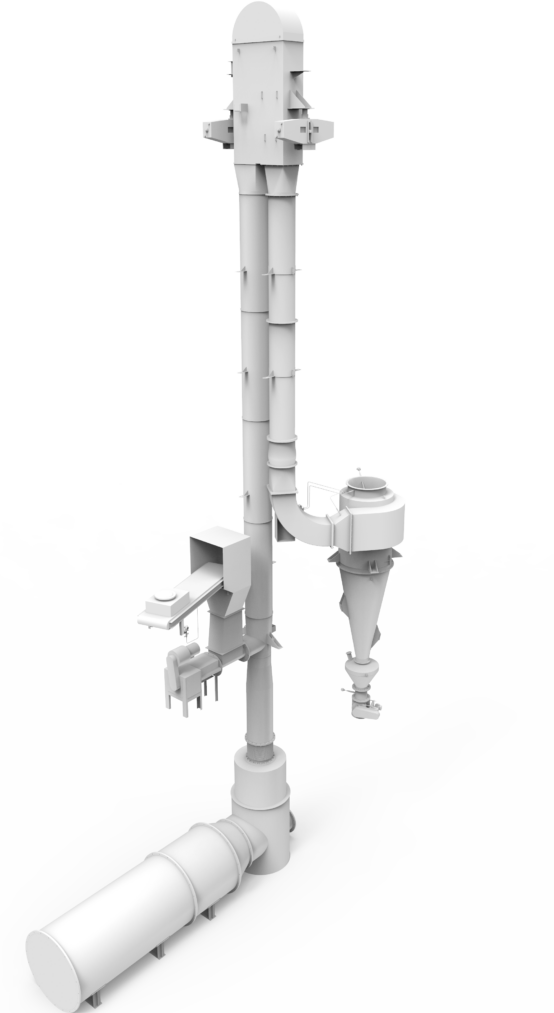

Flash dryer

Principle of the flash dryer is an almost drying by used of hot air pneumatic transport.

This process is particularly suitable for fine and light products.

Learn more

Wet product is introduced into hot air stream through a special Venturi feeder.

Aerodynamic shear forces allow product desintegration into fine elementary particles.

Particles are conveyed along the drying column and recovered by a gas/solid separator (cyclone, bag filter, etc.).

Residence time is resulting from particles volocity and column length.

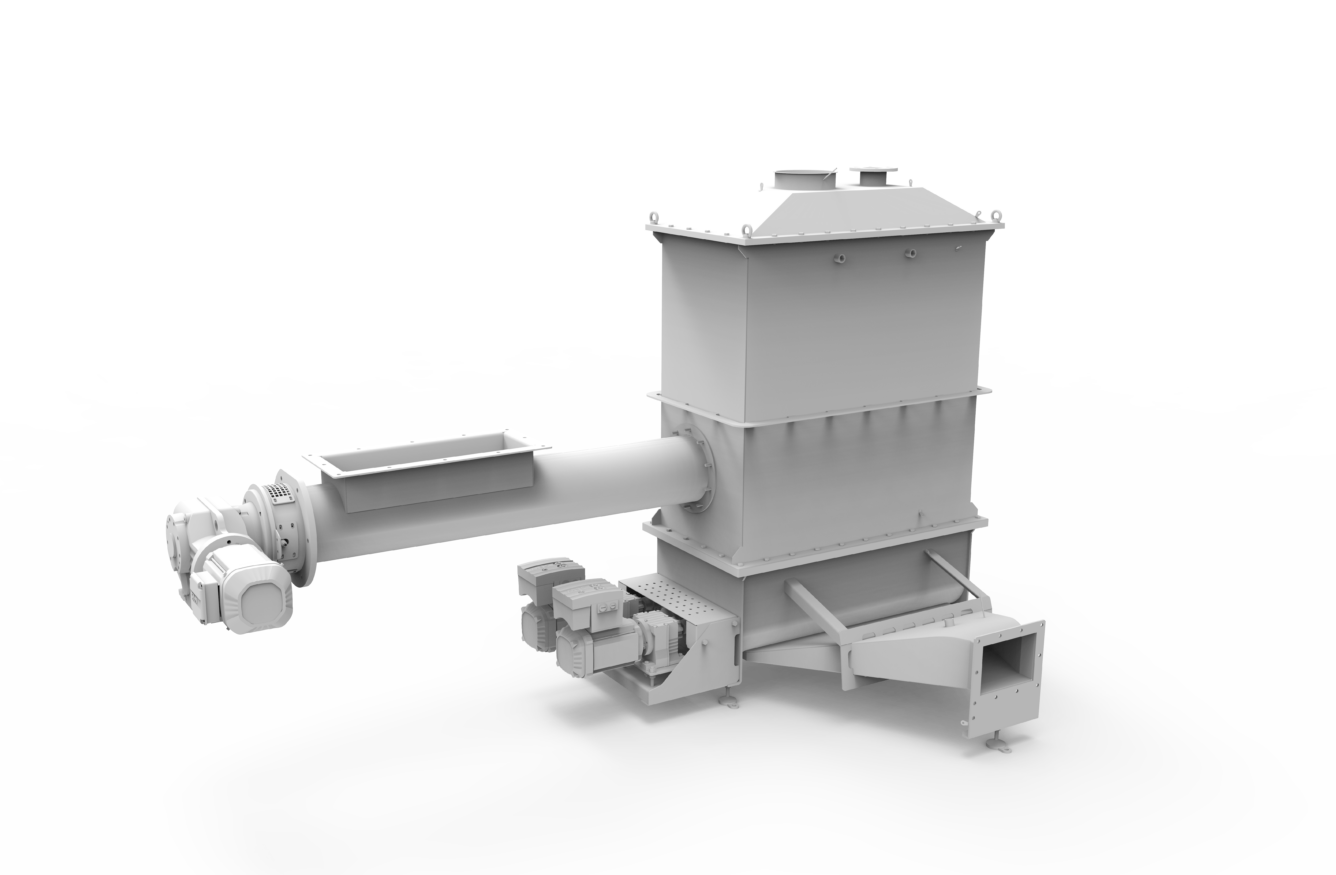

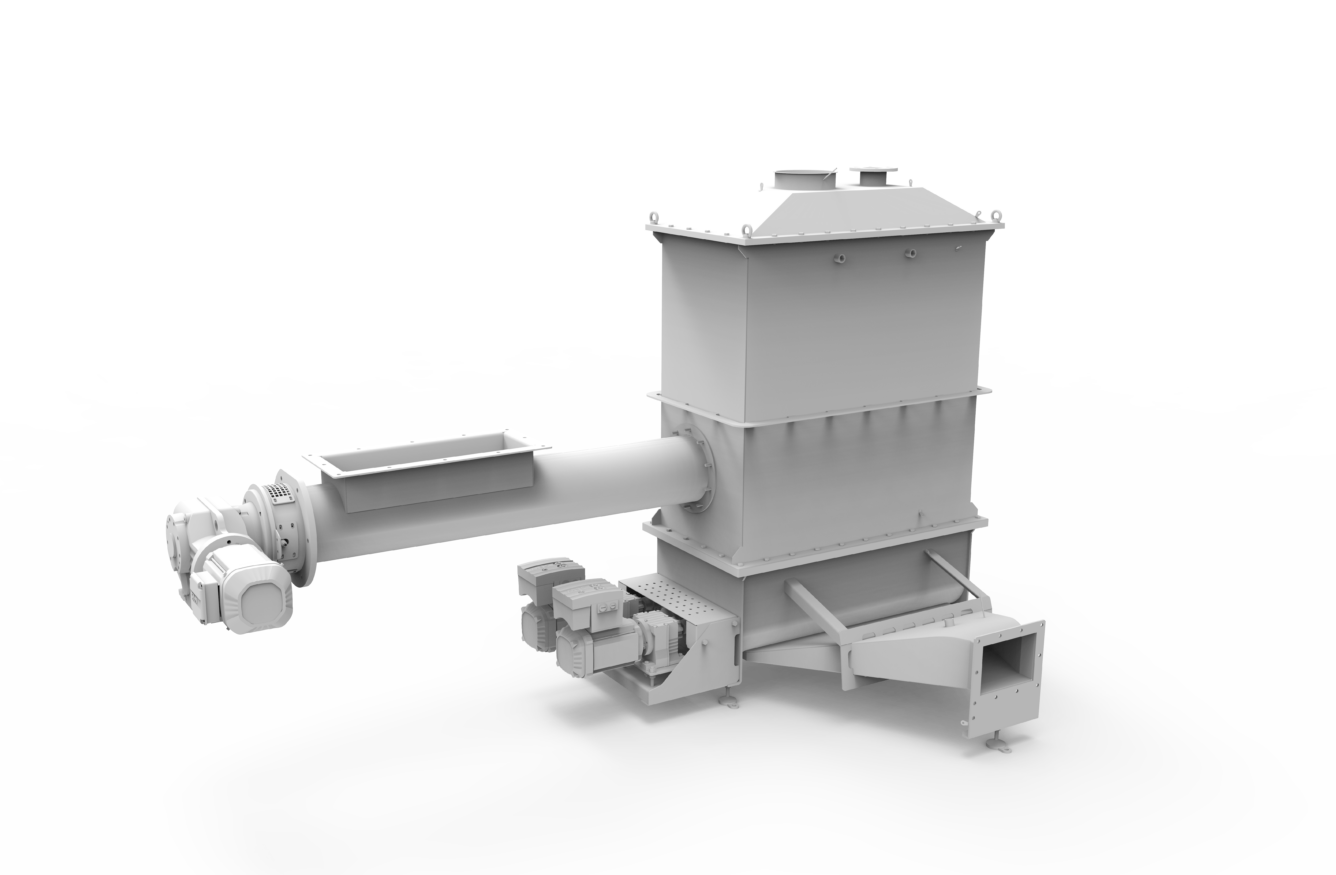

Rapid dryer

Rapid dryer is a compact pneumatic dryer.

It combines a mechanical disintegration with hot turbulent air drying process.

Wet product is continuously fed into a drying plenum. It is mechanically stirred-up by two rotors and passed through by an upward hot gas flow.

Dried particles are pneumatically conveyed outside the plenum and recovered by gas/solid separator (cyclone, bag filter, etc.).

Learn more

Product disintegration increases gas/solid interface and thus heat exchange.

Agglomerates remain at the bottom and until total disintegration, while fine dried particules are pneumatically conveyed to the gas/solid separator.

Product residence time is slightly longer than in a conventional flash dryer.

This alternative to standard flash dryer is much more compact with limited elevation.

Cyclonic dryer

Cyclonic dryer is composed of a cylindrical body with a set of internal conical baffles. Wet product is introduced into the air stream through a Venturi feeder. Gas-solid mixture is tangentially fed at the bottom of the dryer.

Design and numbers of internal baffles are adapted for each application, providing a turbulent swirling flow, thereby highly efficient thermal exchange.

Learn more

Due to internals, product residence time is longer for bigger particles allowing a homogeneous drying. Dried product is leaving the dryer body at the top and is pneumatically conveyed to the separator.

This alternative to standard flash dryer is much more compact with limited foot print.

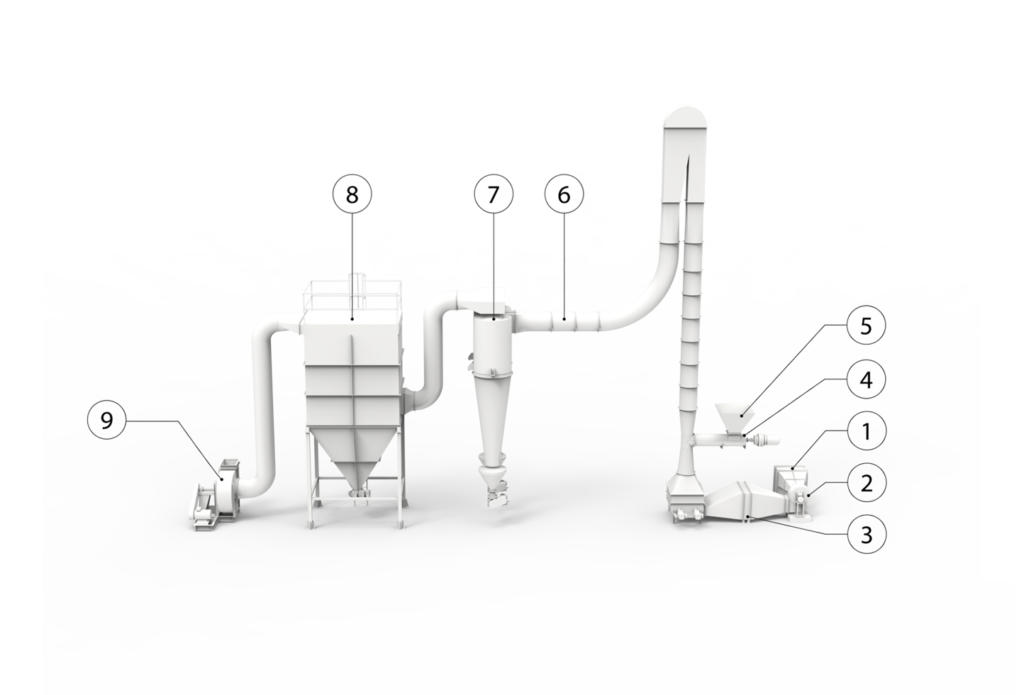

-

Air filter

-

Blower

-

Air heater

-

Feed screw

-

Hopper

-

Flash dryer

-

Cyclone(s)

-

Bag filter

-

Exhaust fan

Complete process unit

Depending on customer’s requirements and applications, COMESSA can provide a complete process unit including ancillary equipment such as: air preparation assemblies, dedusting units (cyclone, filter, scrubber…), instrumentation, automation, etc.

ASK FOR OUR BROCHURE

Ask for our technical equipment leaflets

GERMAN, SPANISH versions available upon request through our contact form.

Test laboratory

COMESSA has its own test laboratory covering more than 1,200 m² offering the possibility of carrying out feasibility tests and semi-industrial tests, for all its technologies.